-

OUTDOOR LED DISPLAY

OUTDOOR LED DISPLAY

-

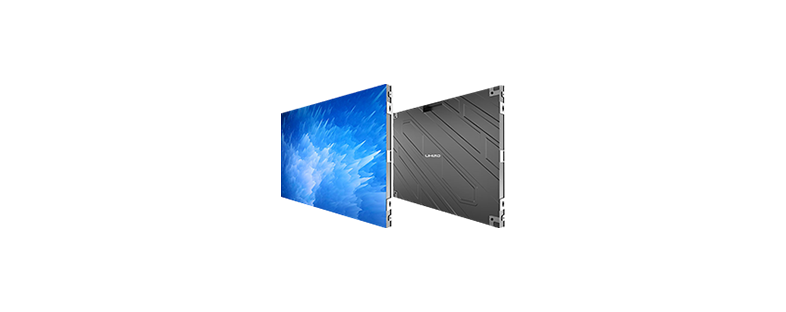

INDOOR LED DISPLAY

INDOOR LED DISPLAY

-

RENTAL LED DISPLAY

RENTAL LED DISPLAY

-

SHELF LED DISPLAY

SHELF LED DISPLAY

-

POSTER LED DISPLAY

POSTER LED DISPLAY

-

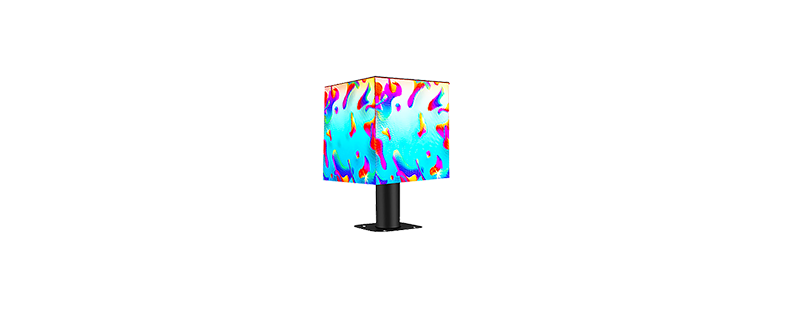

CUBE LED DISPLAY

CUBE LED DISPLAY

-

FLEXIBLE LED FILM

FLEXIBLE LED FILM

- TRANSPARENT LED DISPLAY

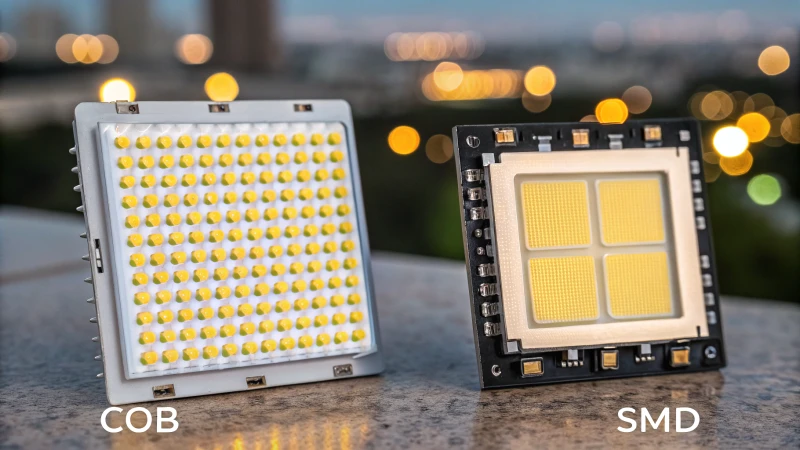

COB LED VS. SMD LED: Key Differences in LED Display Technology

Introduction to LED Display Technologies

In the dynamic landscape of the LED display industry, Chip-on-Board (COB) and Surface-Mounted Device (SMD) LEDs have emerged as the two leading packaging technologies, each with its own unique set of characteristics and applications. These technologies serve as the fundamental building blocks for modern LED displays, powering everything from large-scale outdoor billboards to high-resolution indoor video walls. Despite their shared purpose, COB and SMD LEDs differ significantly in their construction, performance, reliability, and cost, making the choice between them a crucial consideration for manufacturers, integrators, and end-users alike.

Fundamental Construction Differences

SMD (Surface-Mounted Device) Technology

SMD technology has been a mainstay in the LED display industry for decades, and its widespread adoption can be attributed to its mature manufacturing processes and ease of use. At its core, SMD technology involves packaging individual LED chips separately, typically in small plastic or ceramic housings that protect the delicate semiconductor material from environmental damage. These packaged LEDs, often referred to as “SMD packages,” are then mounted directly onto the surface of a printed circuit board (PCB) using automated pick-and-place machines. Each SMD package functions as a discrete component, with its own set of electrical contacts that allow it to be connected to the PCB and integrated into the display circuit.

One of the key advantages of SMD technology is its flexibility in design and assembly. Because each LED is packaged individually, it is relatively easy to replace a faulty component without affecting the rest of the display. This modularity also allows for greater customization in terms of pixel layout and color configuration, as different types of SMD packages can be selected based on specific performance requirements. Additionally, the established manufacturing infrastructure for SMD LEDs means that production costs are generally lower, making it an attractive option for applications where cost is a primary concern.

COB (Chip-on-Board) Technology

In contrast to SMD technology, COB represents a more recent and innovative approach to LED packaging. Instead of packaging each LED chip separately, COB technology involves bonding multiple LED chips directly to a substrate, typically a high-performance ceramic or metal-core PCB. This direct bonding eliminates the need for individual packages, resulting in a more compact and integrated design. The chips are then encapsulated together under a single phosphor coating, which serves to protect the chips from environmental factors and enhance the optical performance of the display.

The elimination of individual packages in COB technology offers several significant advantages. First, it allows for a much higher pixel density, as the chips can be placed closer together without the constraints of individual package sizes. This makes COB an ideal choice for fine-pitch and micro-LED displays, where achieving high resolutions and detailed images is crucial. Second, the direct bonding of the chips to the substrate provides better heat dissipation, as there is less thermal resistance between the chips and the heat sink. This enables higher drive currents and brighter displays without the risk of overheating, improving both the performance and lifespan of the LED modules. However, the more complex manufacturing process and higher initial capital investment required for COB technology can be a barrier to entry for some manufacturers.

Performance Comparison

1. Pixel Density and Resolution

Pixel density is a critical factor in determining the image quality and clarity of an LED display, and it is here that COB technology truly shines. Thanks to its compact chip arrangement and lack of individual packaging, COB displays can achieve significantly higher pixel densities compared to SMD displays. For example, while SMD displays are typically limited to pixel pitches of P1.2mm and above due to the physical size of the individual SMD packages, COB displays can achieve much finer pixel pitches, with some models currently capable of reaching as fine as P0.4mm. This high pixel density translates to higher resolutions and more detailed images, making COB an excellent choice for applications such as high-end retail displays, broadcast studios, and corporate control rooms, where image quality is of utmost importance.

2. Brightness and Efficiency

In terms of brightness and efficiency, both COB and SMD LEDs have their strengths, but COB technology generally offers superior performance. COB displays typically have a higher lumen output per unit area, meaning they can produce brighter images with the same amount of power consumption. This is due in part to the better heat dissipation capabilities of COB technology, which allows for higher drive currents without overheating. Additionally, the direct bonding of the chips to the substrate reduces electrical resistance, further improving the efficiency of the LED modules.

On the other hand, SMD displays may have more consistent brightness across the display, as each individual SMD package can be precisely calibrated during the manufacturing process. This can be an advantage in applications where uniform brightness is critical, such as in large-scale video walls or outdoor billboards. However, the overall brightness and efficiency of SMD displays are often limited by the size and thermal performance of the individual SMD packages.

3. Viewing Angles

Viewing angle is another important performance parameter that can significantly impact the user experience of an LED display. COB displays are known for their wide viewing angles, often capable of providing a full 175° field of view without significant color shift or brightness degradation. This is achieved through the use of a single phosphor coating that encapsulates all the LED chips, which helps to diffuse the light more evenly and reduce the effects of directional lighting. In contrast, SMD displays typically have narrower viewing angles, ranging from 120-140°, due to the individual nature of the SMD packages and the way they emit light. While this may not be a major issue for applications where the display is viewed from a fixed position, it can limit the usability of SMD displays in environments where viewers may be positioned at various angles, such as in public spaces or large conference rooms.

4. Contrast Ratio

Contrast ratio is a measure of the difference in brightness between the darkest and lightest areas of an image, and it plays a crucial role in determining the visual impact and realism of an LED display. COB displays often achieve higher contrast ratios compared to SMD displays, thanks in part to the black surfaces between the COB chips, which absorb more ambient light and reduce glare. Additionally, the use of a single phosphor coating in COB technology helps to minimize light leakage between the pixels, further enhancing the contrast and image quality. In contrast, SMD displays may suffer from lower contrast ratios due to the presence of individual SMD packages, which can allow light to leak between the pixels and reduce the overall contrast of the image.

Reliability and Durability

COB Advantages

When it comes to reliability and durability, COB technology offers several significant advantages over SMD technology. First and foremost, the lack of individual components in COB displays makes them more resistant to physical damage and moisture ingress. Because the LED chips are bonded directly to the substrate and encapsulated together, there are no individual SMD packages that can be dislodged or damaged by impact, vibration, or environmental factors. This makes COB displays an ideal choice for harsh environments, such as outdoor applications, industrial settings, and transportation hubs, where they are exposed to a wide range of environmental stresses.

In addition to their physical robustness, COB displays also have better tolerance to vibration and impact, as the direct bonding of the chips to the substrate provides a more secure and stable connection. This is particularly important for applications where the display may be subject to movement or shock, such as in mobile vehicles or equipment. Furthermore, COB displays have a higher resistance to salt spray and corrosive environments, making them suitable for use in coastal areas or industrial facilities where exposure to harsh chemicals or pollutants is common.

SMD Vulnerabilities

While SMD technology has many advantages,it also has some vulnerabilities when it comes to reliability and durability. One of the main issues with SMD displays is the potential for individual components to fail or be knocked off. Because each SMD package is a discrete component, it can be easily damaged by physical impact, vibration, or temperature fluctuations. This can lead to dead pixels or other visual defects, which can be difficult and costly to repair. Additionally, the solder joints that connect the SMD packages to the PCB may fail over time due to thermal cycling, which can cause the packages to detach from the board and render the display inoperable.

Another vulnerability of SMD displays is their susceptibility to moisture damage. The small gaps between the individual SMD packages can allow moisture to penetrate the display, which can cause corrosion of the electrical components and lead to premature failure. This is particularly a concern for outdoor applications or environments with high humidity levels. To mitigate these risks, SMD displays often require additional protective measures, such as encapsulation or waterproofing, which can add to the overall cost and complexity of the display.

Thermal Management

Effective thermal management is crucial for the performance and lifespan of LED displays, as excessive heat can cause the LED chips to degrade and reduce their brightness and efficiency over time. In this regard, COB technology has a significant advantage over SMD technology, thanks to its direct bonding and more efficient heat dissipation design.

In a COB display, the LED chips are bonded directly to the substrate, which provides a more direct and efficient path for heat to be conducted away from the chips. This reduces the thermal resistance between the chips and the heat sink, allowing for better heat dissipation and lower operating temperatures. Additionally, the use of a high-performance substrate material, such as ceramic or metal-core PCB, further enhances the thermal conductivity of the display, enabling it to handle higher drive currents and brighter displays without overheating.

In contrast, SMD displays rely on the PCB for thermal management, which can be less efficient due to the presence of individual SMD packages and the associated solder joints. The solder joints can act as thermal barriers, increasing the thermal resistance between the LED chips and the PCB and reducing the effectiveness of the heat dissipation. To compensate for this, SMD displays often require additional thermal management measures, such as heat sinks or fans, which can add to the overall cost and complexity of the display.

Manufacturing Considerations

SMD Production

SMD production has a long history in the LED display industry, and as a result, it has well-established manufacturing processes and a mature supply chain. The production of SMD LEDs typically involves several steps, including chip fabrication, packaging, and assembly. The individual LED chips are first fabricated in a semiconductor foundry, and then they are packaged into SMD packages using automated packaging equipment. These packaged LEDs are then mounted onto the PCB using pick-and-place machines, which are highly precise and efficient.

One of the key advantages of SMD production is its lower initial equipment costs. Because the manufacturing processes for SMD LEDs are well-established, the equipment required for production is widely available and relatively affordable. Additionally, the modular nature of SMD displays makes it easier to repair individual failed pixels, as the faulty SMD package can be easily removed and replaced without affecting the rest of the display. This makes SMD displays a popular choice for applications where cost and ease of maintenance are important considerations.

COB Production

COB production, on the other hand, is a more complex and technically challenging process. It involves bonding multiple LED chips directly to a substrate, which requires highly precise and specialized equipment. The chips are typically bonded to the substrate using a process called flip-chip bonding, which involves placing the chips face down onto the substrate and using a conductive adhesive or solder to make the electrical connections. After the chips are bonded, they are encapsulated together under a single phosphor coating, which requires careful control of the coating thickness and uniformity to ensure optimal optical performance.

The more complex manufacturing process of COB technology means that it requires a higher initial capital investment in terms of equipment and facilities. Additionally, the repair of individual chips in a COB display is much more challenging compared to SMD displays, as it often requires specialized equipment and skills to remove and replace the faulty chips without damaging the surrounding components. In many cases, it may be more practical to replace the entire module rather than attempting to repair individual chips, which can increase the cost of maintenance.

Cost Analysis

When it comes to cost, the choice between COB and SMD technology depends on several factors, including the pixel pitch, production volume, and application requirements. Currently, SMD technology generally has lower production costs for standard pitches, as the established manufacturing processes and economies of scale allow for more cost-effective production. This makes SMD displays a popular choice for applications where cost is a primary concern, such as large-scale outdoor billboards or commercial signage.

However, as the pixel pitch decreases and the demand for fine-pitch and micro-LED displays increases, COB technology becomes more cost-competitive. At very fine pixel pitches (<P0.9mm), the advantages of COB technology, such as higher pixel density and better heat dissipation, outweigh the higher production costs, making it a more attractive option for high-end applications. Additionally, COB displays may offer better long-term value due to their higher reliability and durability, as they require less frequent maintenance and replacement compared to SMD displays.

Application Differences

SMD Best For

SMD displays are well-suited for a wide range of applications, particularly those where cost is a primary concern and modular repair is preferred. Some of the common applications for SMD displays include:

- Standard pitch displays (P1.2mm and above):SMD technology is widely used for standard pitch displays, as it offers a good balance between cost and performance. These displays are commonly used in commercial signage, retail displays, and public information displays.

- Cost-sensitive applications:Due to their lower production costs, SMD displays are often the preferred choice for applications where budget constraints are a major factor, such as large-scale outdoor billboards or event displays.

- Environments where modular repair is preferred:The modular nature of SMD displays makes them easy to repair and maintain, as individual SMD packages can be easily replaced without affecting the rest of the display. This makes them a popular choice for applications where downtime needs to be minimized, such as in digital signage networks or control rooms.

COB Best For

COB displays, on the other hand, are ideally suited for applications that require high reliability, wide viewing angles, and high pixel density. Some of the key applications for COB displays include:

- Fine pitch and micro-LED displays:COB technology is the preferred choice for fine pitch and micro-LED displays, as it allows for higher pixel densities and better image quality compared to SMD technology. These displays are commonly used in high-end retail displays, broadcast studios, and corporate control rooms.

- Harsh environments (outdoor, industrial):The high reliability and durability of COB displays make them suitable for use in harsh environments, such as outdoor applications, industrial settings, and transportation hubs. Their resistance to physical damage, moisture ingress, and environmental factors ensures long-term performance and reliability in these challenging conditions.

- Applications requiring high reliability:COB displays are often used in applications where high reliability is critical, such as in command and control centers, financial trading floors, and medical imaging systems. Their robust design and long lifespan make them a reliable choice for these mission-critical applications.

- Situations demanding wide viewing angles:The wide viewing angles of COB displays make them ideal for applications where viewers may be positioned at various angles, such as in public spaces, large conference rooms, or exhibition halls. Their ability to provide consistent image quality and color accuracy from all viewing angles enhances the user experience and makes them a popular choice for these applications.

Future Trends

The LED display industry is constantly evolving, and both COB and SMD technologies are expected to play important roles in its future. In recent years, there has been a growing trend towards the adoption of COB technology, particularly for high-end applications such as corporate control rooms, broadcast studios, and high-end retail displays. This trend is driven by the increasing demand for higher pixel densities, better image quality, and wider viewing angles, as well as the growing awareness of the benefits of COB technology in terms of reliability and durability.

As manufacturing costs continue to decrease and yields improve, COB technology is expected to become more cost-competitive and capture an even larger share of the fine-pitch display market. In addition, advancements in COB technology, such as the development of new packaging materials and manufacturing processes, are likely to further enhance its performance and capabilities, making it an even more attractive option for a wider range of applications.

At the same time, SMD technology is likely to remain dominant in larger pitch applications where cost sensitivity is higher. However, manufacturers are also investing in research and development to improve the performance and efficiency of SMD LEDs, such as by developing new chip designs and packaging technologies. These advancements are expected to help SMD technology maintain its competitiveness in the market and continue to meet the evolving needs of customers.

In addition to the continued development of COB and SMD technologies, there is also growing interest in hybrid solutions that combine the best aspects of both packaging methods. These hybrid solutions aim to leverage the advantages of COB technology, such as high pixel density and better heat dissipation, with the cost-effectiveness and modularity of SMD technology. While hybrid solutions are still in the early stages of development, they have the potential to offer a new level of performance and flexibility in LED display design, and are likely to play an important role in the future of the industry.

Conclusion

In conclusion, both COB and SMD technologies have their own unique strengths and weaknesses, and the choice between them depends on a variety of factors, including specific application requirements, budget considerations, and performance expectations. SMD technology offers a mature and cost-effective solution for standard pitch displays and applications where cost is a primary concern, while COB technology provides superior performance in terms of pixel density, brightness, viewing angles, and reliability, making it an ideal choice for fine pitch and high-end applications.

As the LED display industry continues to evolve, it is likely that both technologies will continue to coexist and complement each other, with each technology serving different market segments and application requirements. By understanding the key differences between COB and SMD LEDs, manufacturers, integrators, and end-users can make informed decisions about which technology is best suited for their specific needs, and ensure that they are able to deliver high-quality, reliable, and cost-effective LED displays that meet the demands of today’s dynamic market.